Servicios al cliente

Sobre nosotros

Copyright © 2025 Desertcart Holdings Limited

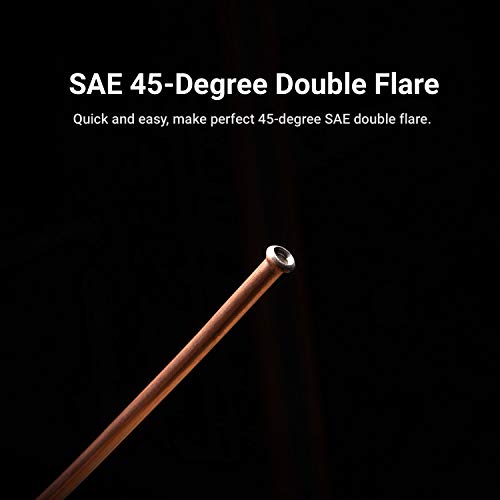

🔩 Master the flare, own the repair—precision in your hands!

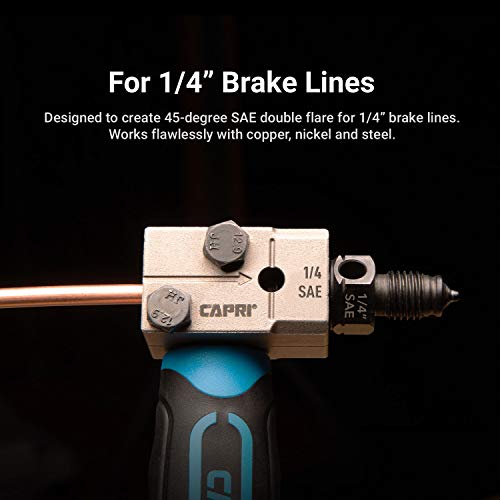

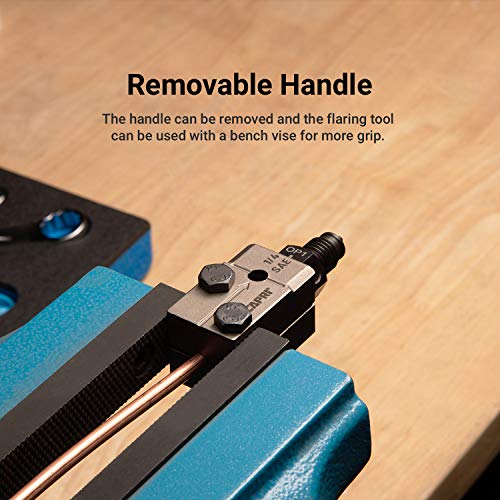

The Capri Tools 1/4 in. Double Flaring Tool is a compact, hand-powered device engineered to produce perfect 45-degree SAE double flares on 1/4 inch brake lines and tubing. Designed for speed and accuracy, it cuts flaring time by 50% compared to older models. Compatible with non-stainless steel, nickel, and copper tubing, its detachable die allows versatile use both handheld and with a bench vise. Lightweight and requiring only two wrenches, this tool is a must-have for professional-grade brake line fabrication and repair.

| ASIN | B08W8D3J2K |

| Batteries Required? | No |

| Batteries included? | No |

| Best Sellers Rank | 11,168 in Automotive ( See Top 100 in Automotive ) 59 in Brake Tools |

| Customer Reviews | 4.6 4.6 out of 5 stars (1,525) |

| Date First Available | 8 Feb. 2021 |

| Included Components | Double Flaring Tool |

| Item Package Quantity | 1 |

| Item Weight | 181 g |

| Item model number | CP21110-14 |

| Manufacturer | Capri Tools |

| Part Number | CP21110-14 |

| Pattern | Flaring Tool |

| Power Source | Hand Powered |

| Product Dimensions | 11.68 x 4.06 x 2.95 cm; 181.44 g |

| Style | 1/4 in. Double Flaring Tool |

A**R

Perfect doubles flares every time

I had also bought one of the cheap vice-held sets that wasn't fit for purpose. This, however, is a good quality item that produces perfect double flares every time. The grip holds the pipe firmly without damage and without needing to overtighten the nuts. The best thing is that all the critical settings, e.g. how far the pipe protrudes, how much the formers should be tightened down, are all controlled so no guesswork is required. Also, the formers are kept square to the pipe producing nice symmetrical flares - this is the big weakness with the cheap sets. Great tool and well worth the money.

A**Y

Really well made

I used this to make up new brake pipes for my Mini Cooper S. For a hand held brake flaring tool it feels solid and really well made unlike some tolls I have used in the past. As its hand help I was able to use t to flare the pipes in situ, this really helped with the job, especially as the idiot (me) managed to damage on of the joining threads after the pip had been laid.

L**T

It works on steel (OE) lines

It does work brilliantly on steel brake lines as well, on the car so saves a lot of time, and quality wise its very nice, only down side to it is there's no case with the variant i got

K**R

Brake flaring tool

This is was my first attempt at replacing brake pipes. This tool made it really easy, created perfect flares on my first attempt. All installed with no leaks. Really good tool, highly recommend!

R**R

Good tool

I tried this on copper nickel lines and factory steel lines. It worked well and produced clean flares but you need to make sure the body is clamped together tightly or it will produce misshapen flares. I would have liked to see it come with a case at this price.

D**T

Great tool

Well engineered tool used on car to bubble and double flair worked a treat. Had to send 4 others different brands back as pipe just slipped back. This capri tool works great. Practice on bench first and if having to use on pipe on car plug pipe if you can and clean pipe to stop it slipping and you should be good.

A**R

Great quality brake pipe tool

Used cheaper sets that weren’t that great at producing quality flares but this is simple, easy to use and produces great quality flares also use if needed with out taking the pipe off the vehicle , bout sure what it’s like with steel pipes though as used on copper, great quality tool

Z**B

Scroll past the others and buy this one...

I never normally leave reviews for products I have bought. But, if you need a flairing tool, spend the extra and buy this. Don't waste your money on the old style. Worth every penny! Perfect flairs every time. I'd give it 6 out of 5 if I could...

D**G

The tool performed perfectly just as advertised. I had great flares first time everytime. Much easier to use then the old style of flare tool. This one just slides on the line to the stop nut you screw in clamp it down. Then you remove the stop nut screw in the #1 die run it down flip the die over #2 run that down and bam perfect flare everytime.

G**N

Better than other pipe flange we have a lot easer to use

J**C

I recently had a line rust out on my 2006 Chrysler 300C. I noticed several years ago that the lines going to the ABS Pump to the master cylinder and both left and right feed lines were getting rusty. Well one finally let loose. I bought stainless 3/16” line and did all four front lines. Master cylinder to abs pump and pump to left and right line. I took my time bending the new line to the same bends as oem. All 4 lines fit perfectly and look great and not a single leak on any of the 8 flares/fittings. (2/line). AWESOME PRODUCT!!! 5 stars!

R**L

This tool performed superbly. It's very solidly made yet compact enough to use in tight spaces. I only had one flare that I had to redo, but that was my fault in not dressing the tube end well enough and not the tool's fault. If you're not producing decent flares it's likely the technique at fault and not the tool - trust me, if I can do it so can you. Cut and dress the end of the tube flat and square. Use a finer file. Heavy score marks left by a coarse file will decrease the odds of a good seal. Lightly de-burr the hole and lightly chamfer the outside edge but don't be too aggressive about it. You don't want to remove too much material, just the excess material. A great tip I picked up from another reviewer is to degrease the tool and the tubing. Use the positioning bolt to set the correct depth and check the fit against the positioning bolt for flat and square through the view holes - both sides - I had one that looked good, but when I looked through the other side it was off just a bit. When tightening down the 3 clamping bolts, there will be one bolt to the side of the brake line and two to the other side. I suggest tightening the bolt that sits alone first, then tighten the other two, alternating across all three to really snug the clamp down. Doing this helps create a lever action to really clamp the tubing tightly. The bolts are good quality Grade 12.9, they'll take quite a bit of torque. I used my 10mm brake bleeder wrench (longer than a standard wrench) and was able to get them pretty tight. Last, make sure you grease the die completely, don't overdo but make sure you get down around the nipple that goes into the tube. If you're flaring vinyl coated factory lines you may have to remove the coating first. Mine was so thick I couldn't even get the flare nut on. I heated up an old flaring nut to push most of the coating back then followed up with a razor knife and 220 grit sand paper. Just be careful not to remove metal, especially at the end where you'll be making your flare. Some others noted that the tool will leave "witness" lines. That is true, but they can be easily addressed with a file and they do not extend to the formed flare itself. They should not interfere with the seal, but I did find that they can cause the flare nut to bind when pushing it up to newly formed flare. Although I didn't use double flares I did do a test flare. The mating surface looked OK, but the flare are was slightly asymmetric. This might be due to the torque the die place on the line. Ideally you want pressure and not torque, which is the purpose in greasing the die. If I were to try again, I think I would drive the die in part way remove and re-grease. I was less impressed with the SAE flare, but the DIN was spot on. I hope that helps.

A**R

This is an excellent tool. Nearly fool proof, just don't forget the tube nut, don't forget to grease the die, and work it back and forth as you run the die in. I like to go 1/3 forward, 1/6 turn back as I run the die in. I am using 4lifetimes stainless tubing, it is fairly malleable and I haven't had a flare split on me yet! Can't speak for other cheap tubing though. This is a tool that will last a lifetime and worth every penny!!

Trustpilot

Hace 1 mes

Hace 2 meses