Servicios al cliente

Sobre nosotros

Copyright © 2025 Desertcart Holdings Limited

⚙️ Elevate your CNC game with precision, power, and pro-level versatility!

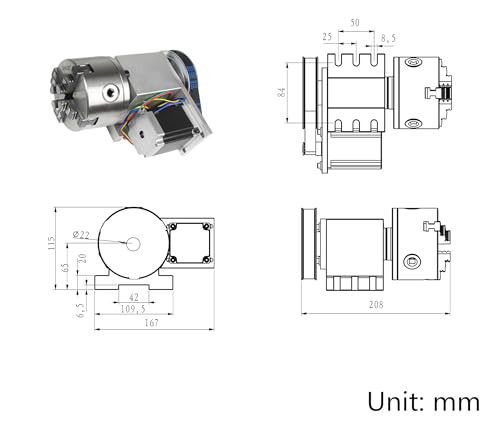

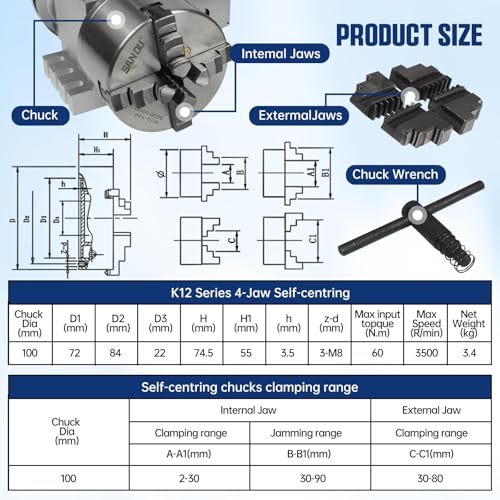

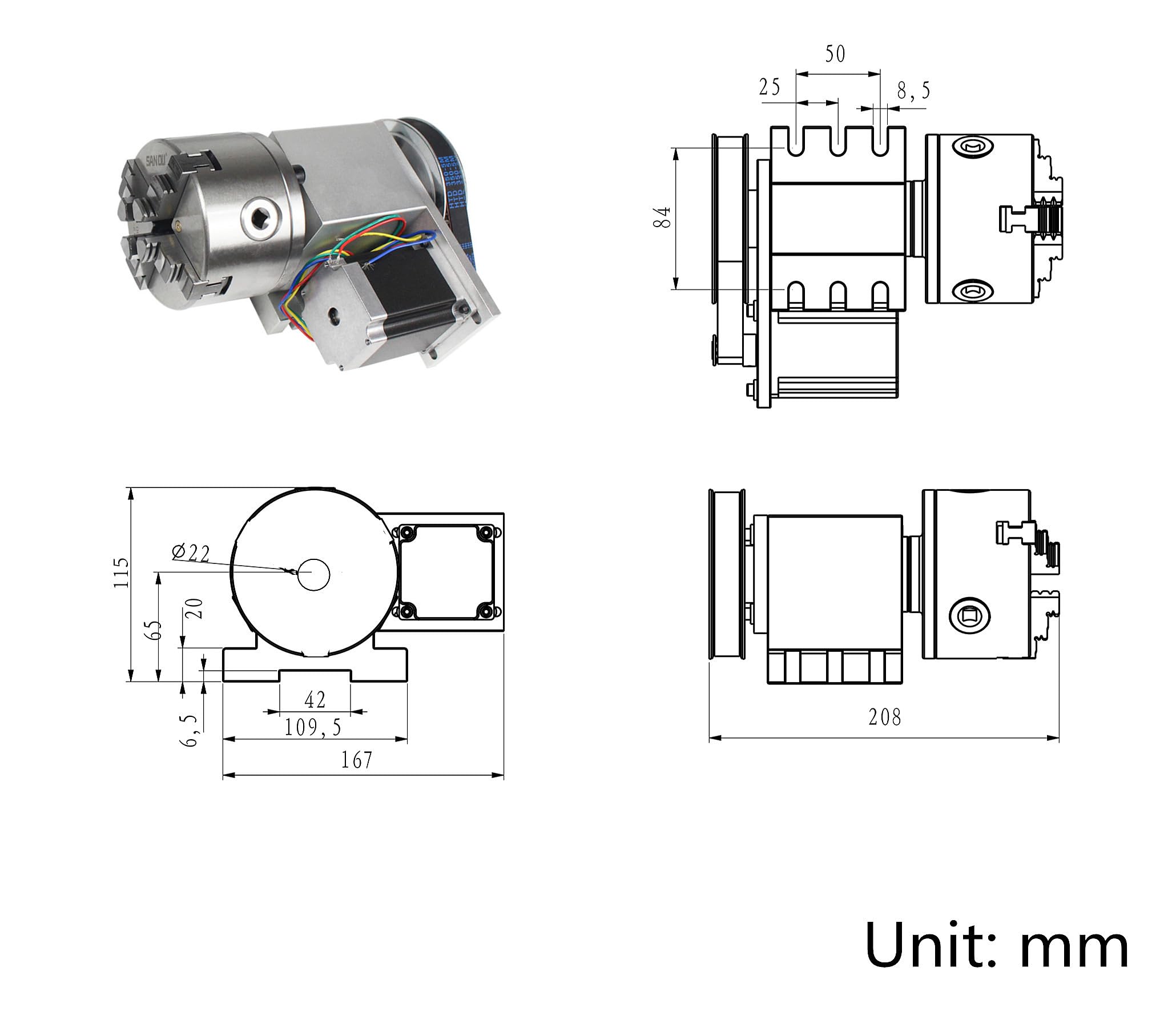

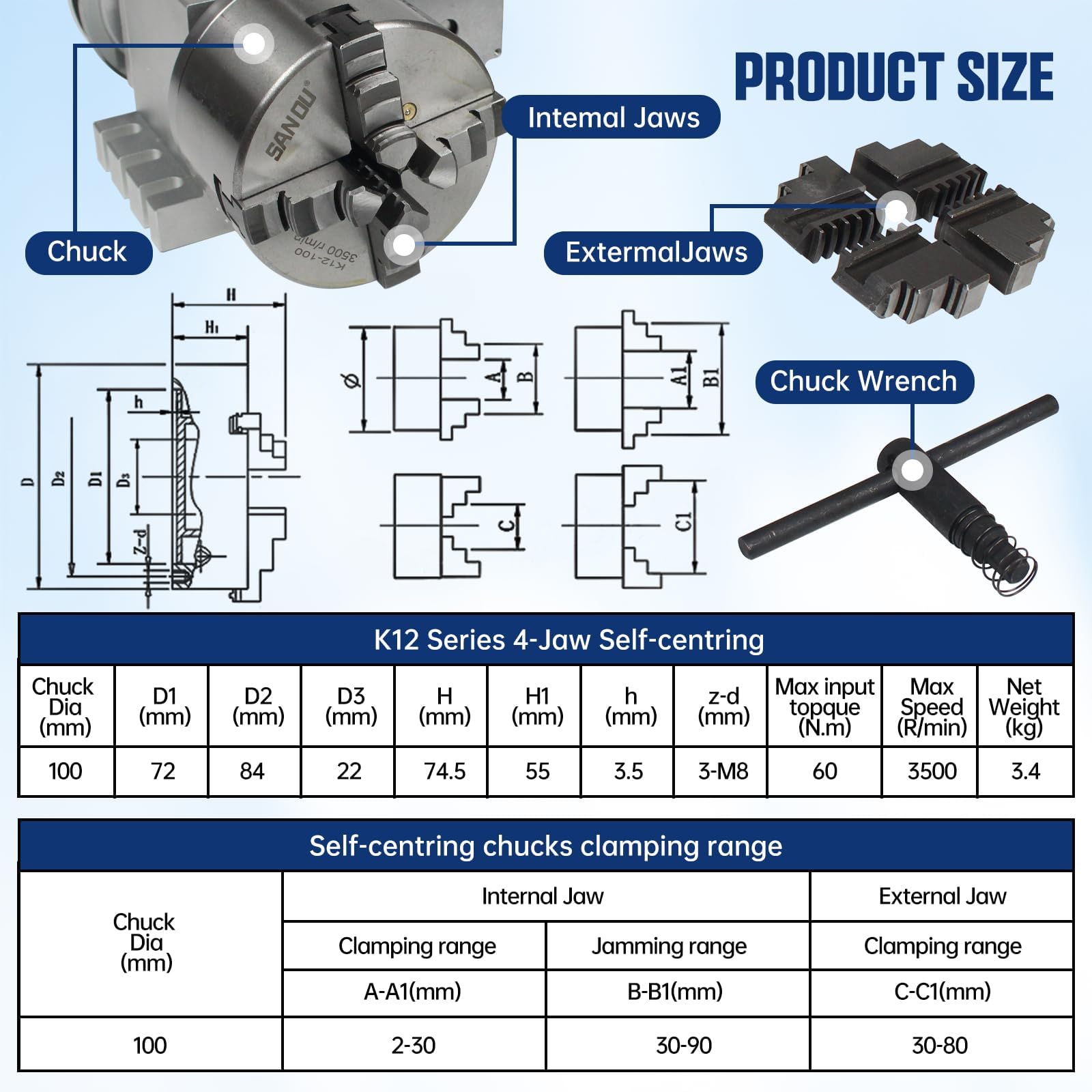

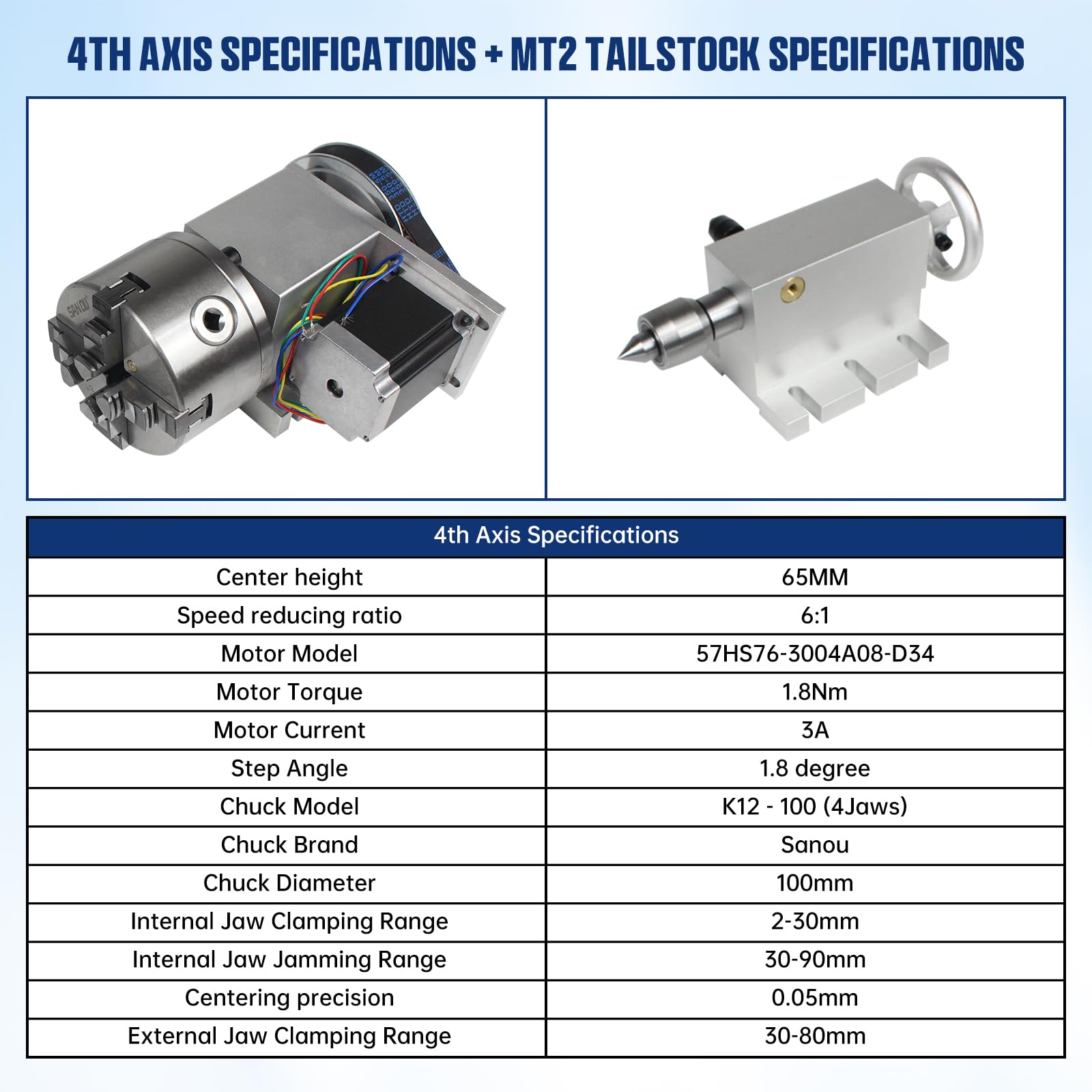

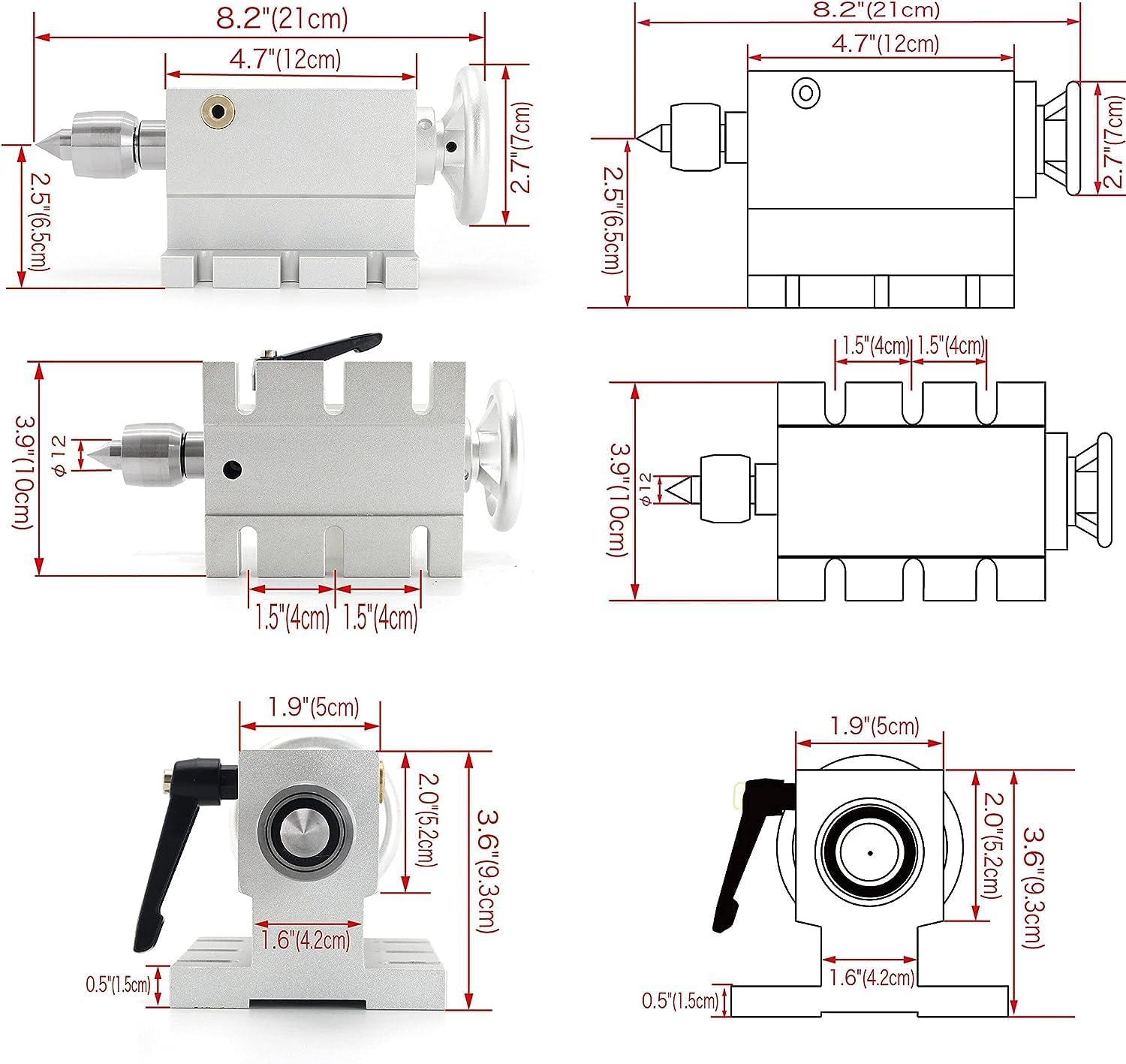

The K12-100mm CNC Router 4th Axis Rotary Table combines a high-torque NEMA23 stepper motor with a 6:1 reduction gearbox and a 100mm 4-jaw self-centering chuck. Featuring a 65mm MT2 live center tailstock and an aluminum alloy base, it delivers precise 0.3° step increments and stable, rust-resistant operation. Designed for advanced 3D cylindrical and spiral engraving, it integrates smoothly with popular CNC control systems, making it a must-have upgrade for professional-grade milling and engraving projects.

| ASIN | B07B2RX1BK |

| Batteries Required? | No |

| Batteries included? | No |

| Best Sellers Rank | 137,967 in Business, Industry & Science ( See Top 100 in Business, Industry & Science ) 88 in Power Milling Machines |

| Capacity | 100 Millimetres |

| Customer Reviews | 4.1 4.1 out of 5 stars (40) |

| Cutting Diameter | 1E+2 Millimetres |

| Date First Available | 12 May 2017 |

| Included components | 4th axis K12 100mm, stepper motor, 4 jaw chuck, 65mm Tailstock |

| Item Package Quantity | 1 |

| Item Weight | 10.2 kg |

| Item model number | S23 |

| Manufacturer | Changzhou Rattm Motor Co.,Ltd |

| Package Dimensions | 43.18 x 30.48 x 22.86 cm; 10.23 kg |

| Part Number | S23 |

| Pattern | 4th-A |

| Style | Style-4th-A |

| Thread size | MT2 |

| UPC | 785004502711 |

A**R

I received a new 4th. Axis from the seller, and this one works fine!...Kudos to the seller for sending me a new one even when I was out of the Amazon’s return window. After I opened the box and manually tested it I realized that the new one was able to spin without much effort, opposite to the first one I got that it was hard to rotate, but since I didn’t know what to expect I thought it was fine and hard to rotate due to the stepper motor (I didn’t remove it). So here is my recommendation if you get one of these: Recommendation Once you receive your package, unscrew and remove the stepper motor (completely), as if you were trying to adjust the belt tension; this shouldn’t void your warranty as you should be able to adjust the belt any time and this is not opening the spindle. Now and without the stepper motor, manually rotate the spindle/chuck; the spindle/chuck should rotate freely, without much effort but not as a skateboard wheel; great if does. Even if you feel a small amount of friction it should be fine as it should be normal on these spindles/chucks. If you have a hard time rotating it (and hear something like a clicking sound) then you should be considering exchange it. Hope this helps. Note: I’m leaving my original comment below in case you were following… Original Comment: Disappointed!...The spindle it's barely turning and seemed to got stuck only after a few times using it. this happened right after my Amazon return window expired, so I contacted the seller for diagrams to see if I could open it and do some clean up or add grease, but they do not have any. The seller suggested to "hammer the inside four claws from the front to the back" but that seems radical and I'm not certain it will not damage completely the spindle. I have seen videos of other 4th axis that they have retainers/big nuts that you unscrew to open the interior, but this model has none; not in the back or in the front, and I have not found a site or video that shows how to open any of these models. Do not recommend. UPDATE 10/9/2019 The seller contacted me again and as there are no schematics available, then it's willing to help me solve the issue in a different way; by sending me a new product for testing and review, and have expedited the shipment. I'll provide new comments an possible update the overall rating once I have tested and reviewed the new product.

B**L

Really nice quality for the price! The motion is very smooth, with zero perceptible backlash. Unfortunately, I did have to return it. No fault of the product itself, but due to unforeseen controller issues on my end. The unit is very difficult to backdrive, thanks to the 50:1 harmonic drive. The NEMA 23 motors may look small, but it's no issue, again, thanks to the drive ratio. If you ask nicely, the seller will provide you with a CAD file of the unit to help with programming.

A**R

Not sure what the other reviewers are talking about there is a ton of backlash. Out of the box the belt tension is far too low. Even after adjusting that, there is way too much backlash to use this for a proper milling set up. Not sure what it’s any good for.

A**R

Very solid motor gearbox. I am pleased with the craftsmanship of this robotic joint and look forward to activating it in a robot arm.

C**R

Finally got around to hooking it up. The center is off by 40 thousandths! Don’t buy!!!

Trustpilot

Hace 2 meses

Hace 1 día